French flair

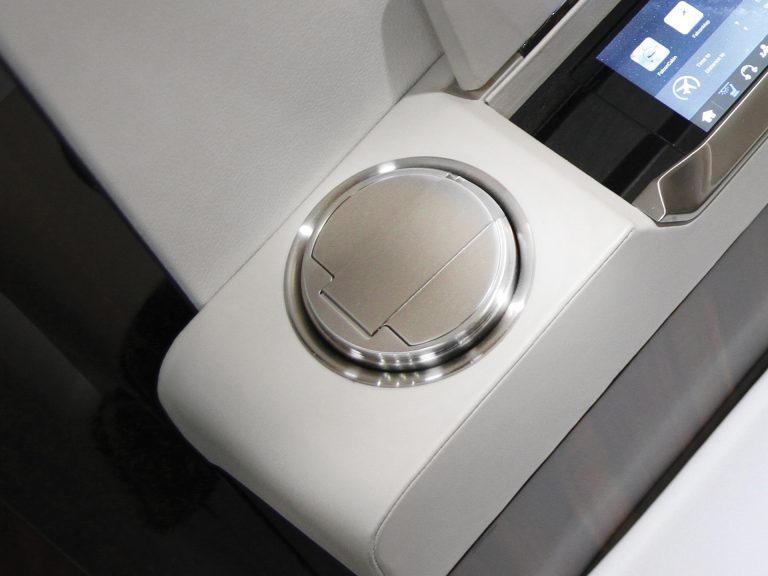

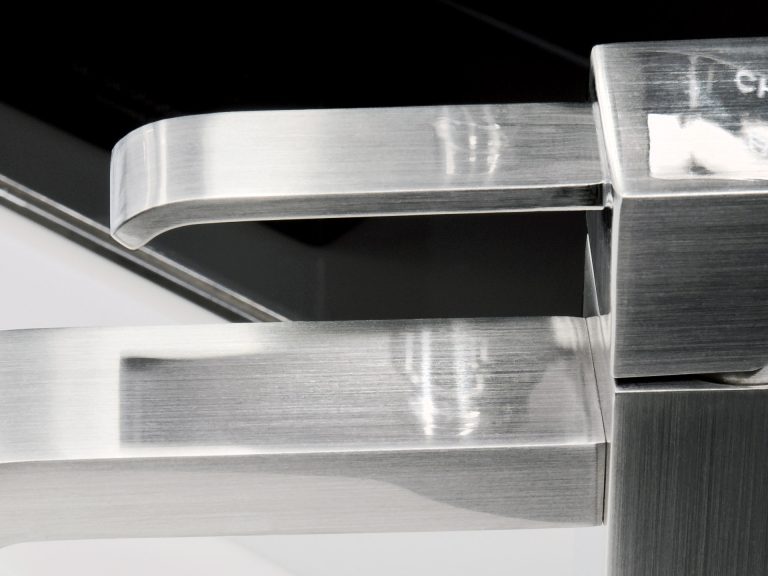

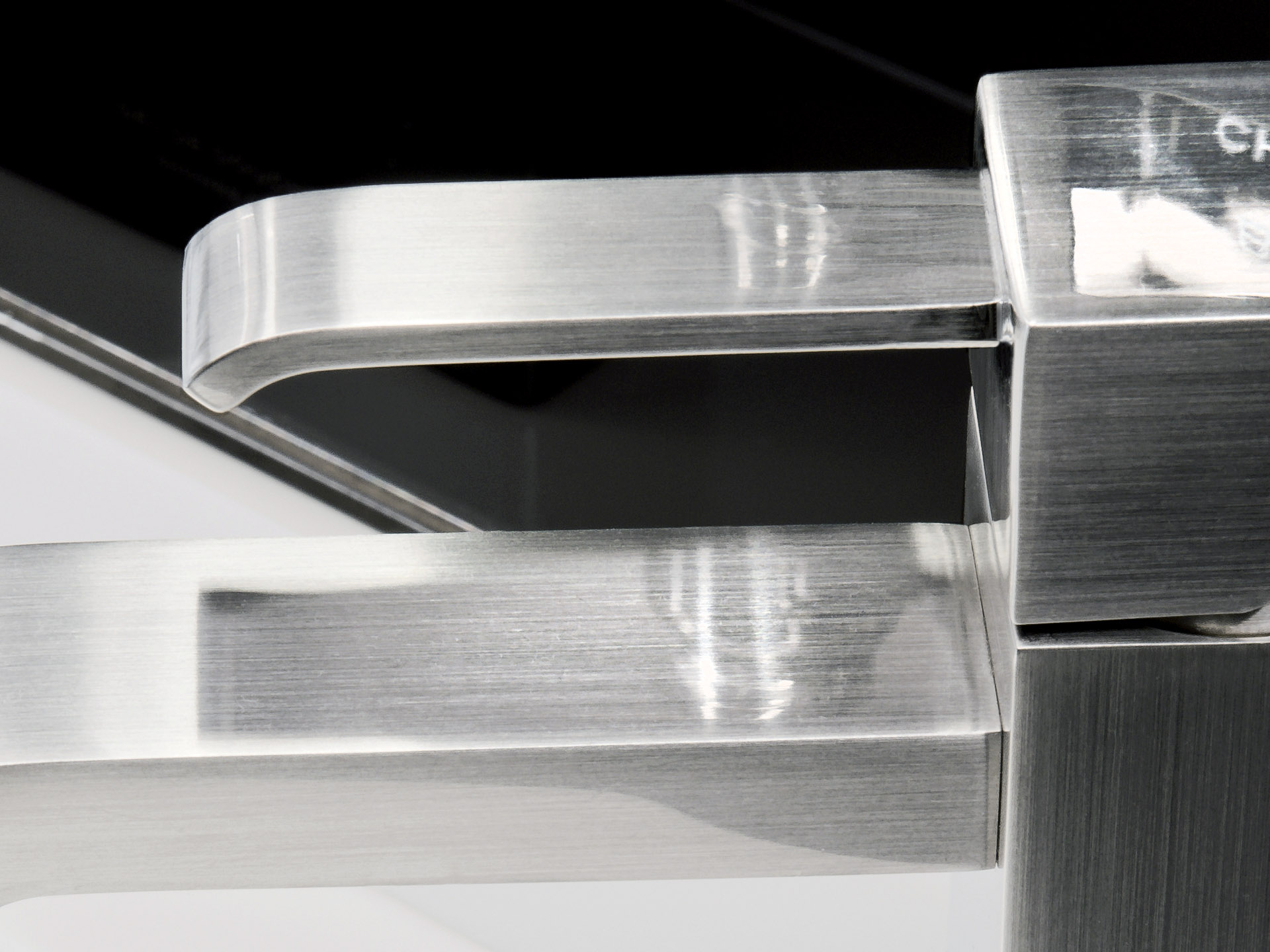

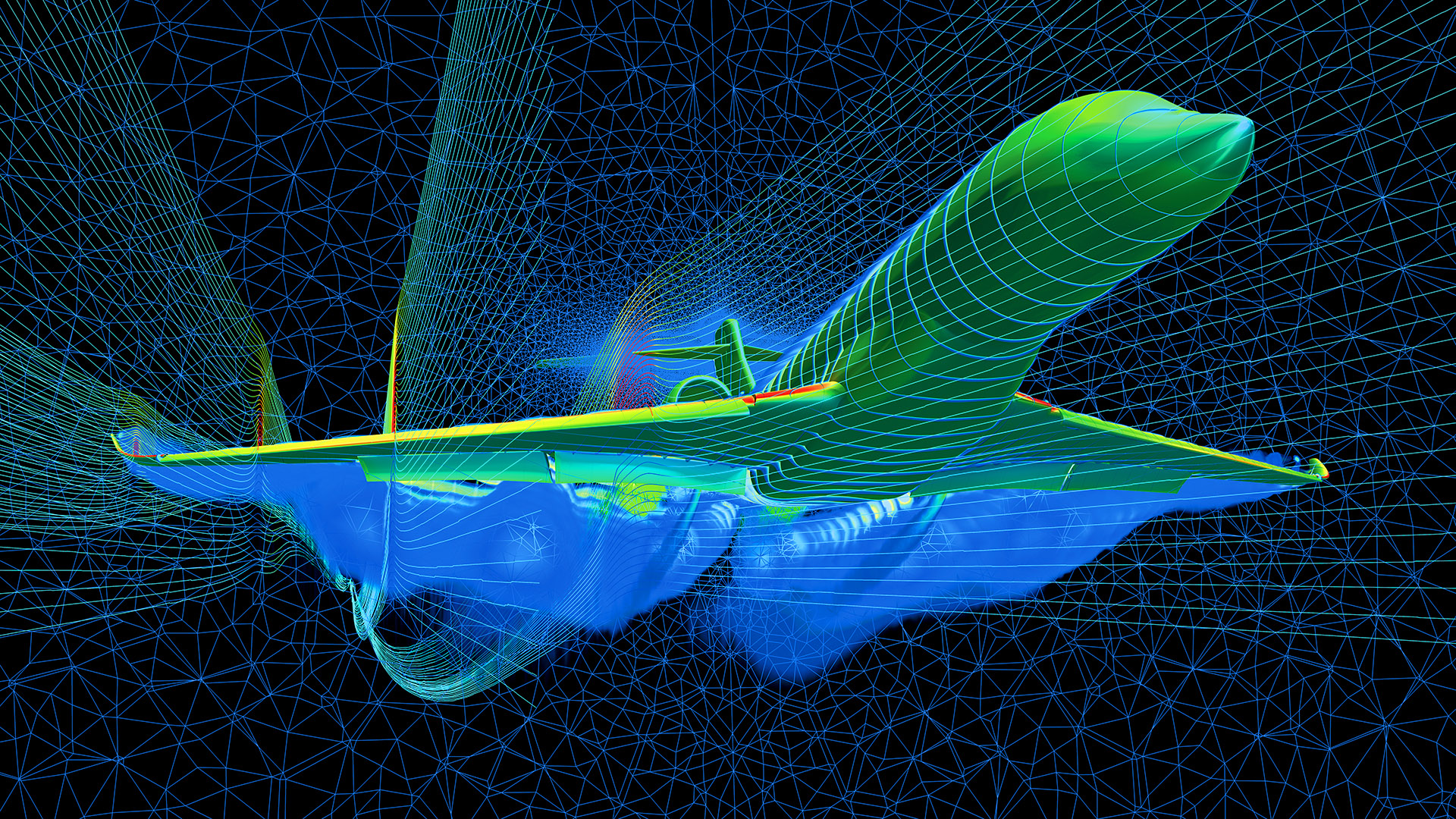

It’s no surprise that the international word for elegance is “chic.” Dassault designers are routinely awarded for their stunning and inventive work. As a Falcon owner, you will have an opportunity to collaborate with a team who will lend their deep experience and style sense to achieve the cabin of your dreams.