What is DFCS and why is it important?

DFCS, often referred to as a “fly-by-wire”, replaces the manual linkages that connect cockpit controls and flight control surfaces on conventional aircraft with electronic cables. These cables transmit signals generated by the pilot’s sidestick to flight control computers, which then interpret the best combination of control inputs and send the signals on to actuators that move the control surfaces.

Digital flight controls save weight and improve reliability. They make handling more precise, reduce pilot workload, and, most critically, provide flight envelope protections that ensure a safer and smoother flight.

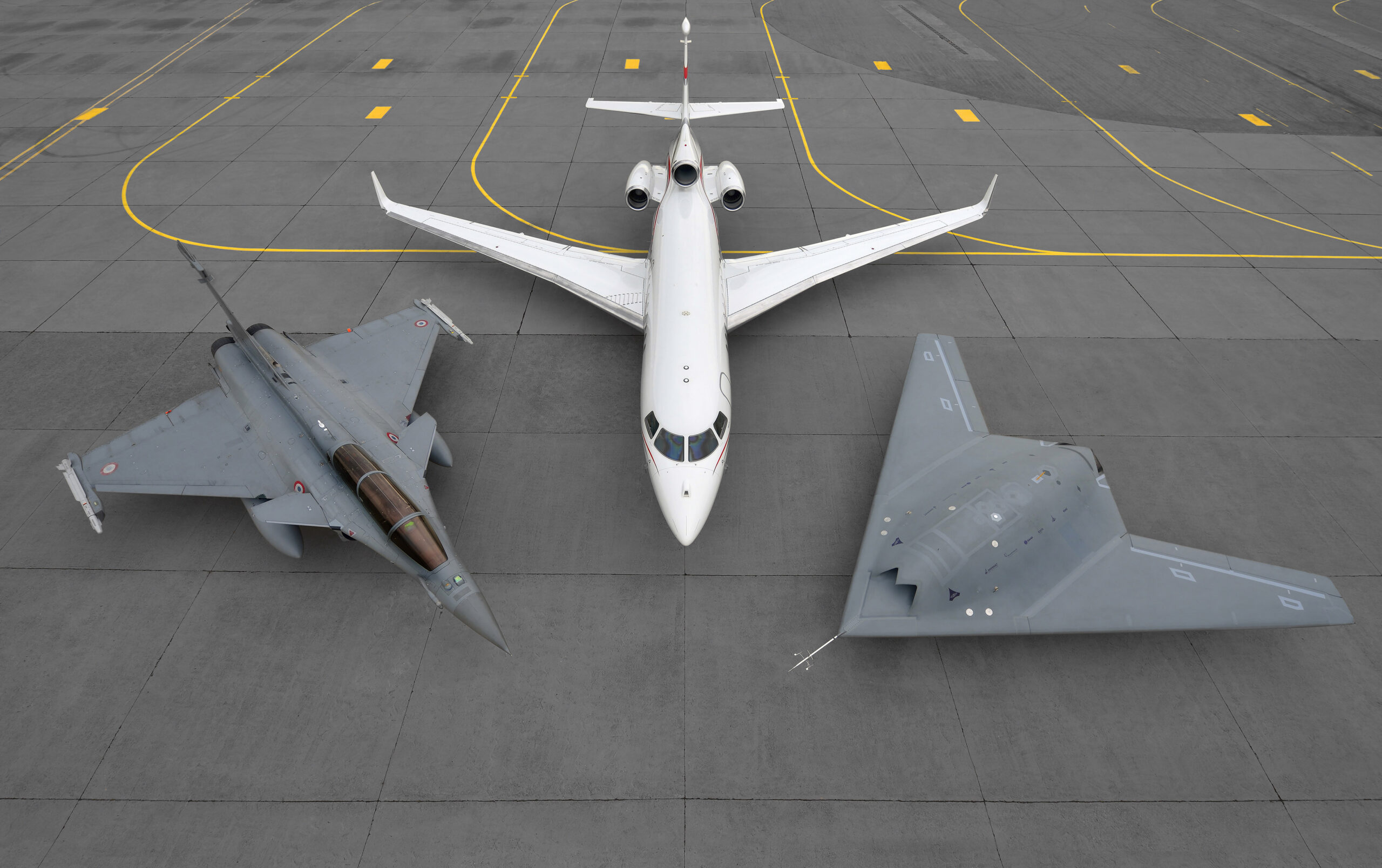

The “magic” in DFCS has much to do with experience in programming flight laws. In the business aviation realm, no company has more experience in developing control laws and related hardware for digital flight control systems than Dassault. Indeed, the company is renowned across the aerospace industry as a pioneer in DFCS technology and flight control laws, which it has steadily refined and improved on a long line of Mirage and Rafale fighters dating back to the 1970s.

The first fly-by-wire business jet

Dassault introduced digital fly-by-wire into business aviation with the Falcon 7X, which entered service in 2007.

Unlike previous generations of FBW technology, which employed analog technology, the 7X was designed with a fully digital flight control system that drew on Dassault’s five decades of experience with fighter aircraft and its deep expertise in programming flight control laws, in particular the complex algorithms governing the behavior of a digital fly-by-wire system. In adopting DFCS technology for the 7X and later Falcon models, Dassault engineers were guided by several objectives:

- Reduce workload in order to allow pilots to focus on higher-level flight management tasks.

- Prevent the aircraft from exceeding its safe flight envelope without impacting optimum flight performance.

- Free up flight deck space by doing away with heavy mechanical control yokes.

- Reduce aircraft weight and maintenance by eliminating push rods and other physical connections to flight control surfaces.

- Dampen the effects of turbulence and reduce stress on control surfaces.

- Optimize wing shape, cruise performance and low-speed flight characteristics.

- Optimize the aircraft for cruise efficiency and reduced fuel consumption. By optimizing the shape of the wing and the size and position of the stabilizer, the gap between the center of gravity and the center of lift can be closed, reducing drag.

- Provide protection in the event of control surface damage. If an elevator, for example, becomes inoperative, DFCS automatically substitutes alternative control inputs to mitigate damage.

The DFCS on the Falcon 7X, based on that of the Rafale fighter, introduced a “path-stable” system that trims automatically to maintain the flight path of the airplane, reducing pilot workload while providing a smoother ride for passengers.

On the Falcon 7X, the pilot does not need to constantly correct for small disturbances or apply intermittent trim to adjust for speed changes or changes in aircraft configuration, e.g. by extending or retracting the flaps. In fact, the sidestick on the 7X does not even have a trim switch because the DFCS automatically trims the aircraft, significantly decreasing the pilot’s workload.

How does DFCS work?

Digital flight control systems take inputs from the pilot through the sidestick. A series of redundant computers analyze electronic pilot inputs and then adjust flight controls to manage the flight path.

On the Falcon 7X, twenty sensors on each sidestick transmits pilot inputs to a bank of three primary flight control computers and three secondary backup computers. The primary and secondary computers, in turn, are backed up by an emergency analog system.

This is a considerable level of redundancy, as only one computer is required to fly the airplane.

In normal flight situations, the primary flight control computers direct a combination of flight controls to perform the desired maneuver. The full DFCS system is employed to provide flight envelope protection, preventing stall or overspeed for example, and providing auto-trim along all three axes (pitch, roll and yaw).

The smart sidestick

All Falcons equipped with a DFCS employ smart sidestick controls, which alter the current flight trajectory, both vertically and laterally, by adjusting a combination of control surfaces to achieve the desired flight path. Often referred to as “path stable,” these controls automatically adjust flight control surfaces for the right combination of pitch and roll to hold the flight path—as on a typical advanced fighter aircraft.

On takeoff, for example, the pilot rotates, holds attitude for a second and then releases pressure. The path is set and the DFCS auto-trims to hold it stable as the crew retracts the gear and the aircraft accelerates. The pilot then adjusts the flight path for second stage climb and again releases pressure. If Air Traffic Control orders a climbing turn, the pilot banks the aircraft, maintains the climb and can then once again release pressure on the sidestick. All of this allows the pilot to focus his or her attention on more flight critical tasks, ensuring improved safety and a smoother ride for the passengers.

On approach to landing, the DFCS reduces pilot workload, too–in particular by eliminating the need to constantly trim the horizontal stabilizer as speed is reduced and the wings are configured for landing. This important approach aid also contributes to safer and smoother operation.

By associating smart sidesticks with DFCS technology, Dassault has been able to retain the renowned agility of Falcon aircraft without generating the heavy workload typically incurred in hand flying a high-speed business jet. Moreover, this innovative flight path control technology is easy to adapt to, and quickly becomes intuitive.

Active sidesticks versus smart sidesticks

Some business jets from other manufacturers use “active” sidesticks. These mimic the behavior of control yokes installed on aircraft with conventional mechanical flight control systems. The sidesticks are electrically coupled so that they appear to be mechanically linked side by side and therefore move in tandem.

Active sidesticks can show one pilot how the other pilot is manipulating his or her sidestick but control movement may not provide much information on the real flight path of the aircraft or how the flight controls are actually reacting. The same is true when observing active sidestick movements with the autopilot engaged.

While active or coupled controls typically facilitate basic flight training on a small airplane, their value in a high-performance jet has to be balanced against their cost in weight, complexity and failure risk. A large panel of pilots assessed the use of coupled controls in the early stages of the Falcon 7X program and again during development of the 8X and 6X. But in the end, the consensus was that smart sidesticks more suitably matched the requirements of advanced Digital Flight Control Systems.

Understanding two different design philosophies–“open-loop” and “closed-loop”

DFCS technology used on Falcon aircraft differs considerably from “open-loop” conventional fly-by-wire systems, which merely try to replicate conventional flight control systems and inputs.

Open-loop systems fly very much like aircraft with conventional control linkages. In an open-loop airplane, the pilot must provide continuous input (feedback) to maintain a desired flight path and manually trim to alleviate pressure from changes in speed.

A closed-loop DFCS works more like cruise control on an automobile. It continuously and automatically maintains the aircraft trajectory requested by the pilot and uses multiple flight surfaces to maintain the trajectory until the next pilot input is received.

Dassault’s design philosophy is based on the premise that the primary role of the pilot in a modern business jet should be to manage the flight and that he or she should spend as little time as possible providing feedback to the flight control system.

The origins, evolution and future of Dassault’s digital flight control systems

In the 50s and 60s, the Dassault Flight Control Department introduced limited-authority electro-hydraulic links. In the late 70s, it designed the Mirage 2000 fighter, which was equipped with a full analog fly-by-wire control system. The 2000 was intentionally designed to be dynamically unstable and thus highly maneuverable. Electronic flight controls were required for safe and predictable handling.

A decade later came full digital flight control with the Rafale fighter. On May 5, 2005, the Falcon 7X business jet took to the skies, equipped with a digital flight control system adapted from the Rafale.

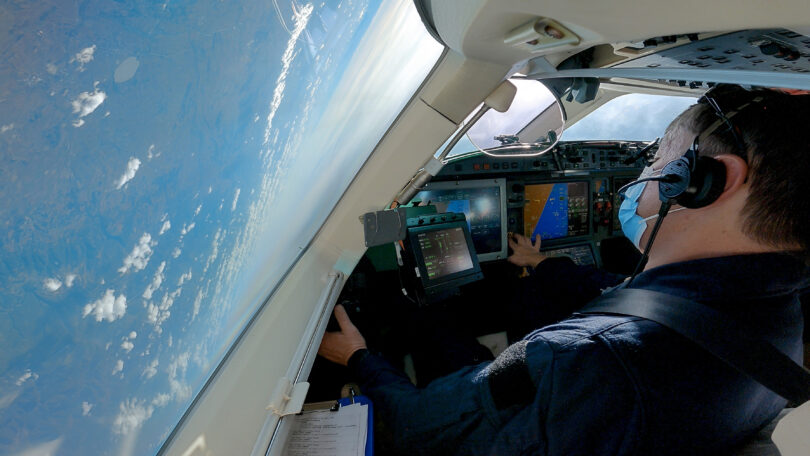

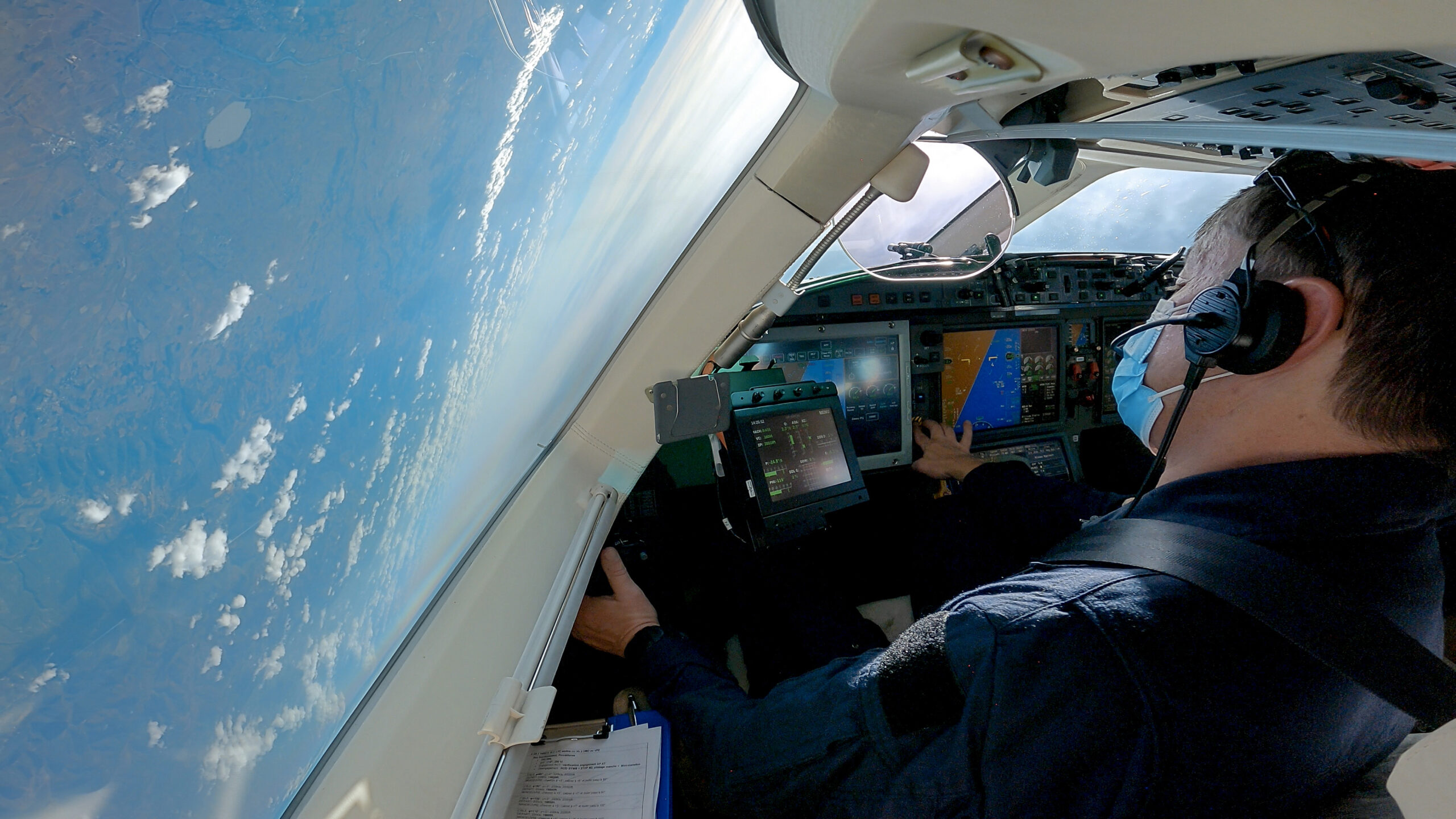

The Falcon 6X made its first flight on May 10, 2021 introducing a new generation of DFCS. On the 6X, DFCS controls all flight controls–not only primary controls, as on the 7X and 8X, but secondary controls such as flaps and slats, plus a new control called a flaperon that combines the actions of flaps and ailerons. The 6X’s DFCS also controls nosewheel steering, permitting safer runway handling in strong crosswinds and wet runway conditions. The 6X was substantially through its flight test campaign by July 2022 with entry into service planned for mid-2023.

Ob May 6, 2021, Dassault unveiled the Falcon 10X with an advanced DFCS incorporating new safety features:

- A single-lever Smart Throttle controlling both engines, a breakthrough derived from the mono-throttle on the twin-engine Rafale fighter jet. The Smart Throttle simplifies normal procedures such as noise abatement climbs as well as one-engine-inoperative procedures.

- The digital Smart Throttle is fully integrated with the DFCS to enable an upset recovery mode that can return the aircraft to straight and level flight in the event of a wake turbulence upset or other loss of control scenario.

The company expects to certify the 10X at the end of 2025.